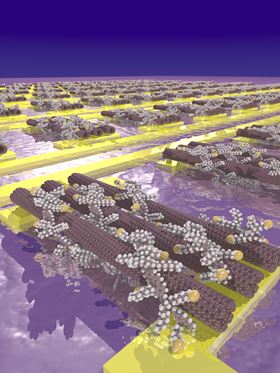

This is an artist's impression of carbon nanotubes wrapped in polymers with thiol side chains (yellow spheres) and assembled on gold electrodes. Image: Arjen Kamp.

This is an artist's impression of carbon nanotubes wrapped in polymers with thiol side chains (yellow spheres) and assembled on gold electrodes. Image: Arjen Kamp.Carbon nanotubes can be used to make very small electronic devices, but they are difficult to handle. Scientists at the University of Groningen in the Netherlands, together with colleagues from the University of Wuppertal in Germany and IBM Zurich in Switzerland, have now developed a method to select semiconducting nanotubes from a solution and make them self-assemble on a circuit of gold electrodes. They report this work in a paper in Advanced Materials.

The results look deceptively simple: a self-assembled transistor with nearly 100% purity and very high electron mobility. But it took 10 years to get there. Maria Antonietta Loi, professor of photophysics and optoelectronics at the University of Groningen, designed polymers that wrap themselves around specific carbon nanotubes in a solution of mixed tubes. Sulphur-containing thiol side chains on the polymer then bind the tubes to the gold electrodes, producing the resultant transistor.

“In our previous work, we learned a lot about how polymers attach to specific carbon nanotubes,” Loi explains. Carbon nanotubes can be depicted as a rolled up sheet of graphene, the two-dimensional form of carbon. “Depending on the way the sheets are rolled up, they have properties ranging from semiconductor to semi-metallic to metallic.” Only the semiconductor nanotubes can be used to fabricate transistors, but current production processes always generate a mixture of all different types of carbon nanotubes.

“We had the idea of using polymers with thiol side chains some time ago,” says Loi. The idea is that as sulphur naturally binds to metals, the thiol side-chains will direct the polymer-wrapped nanotubes towards the gold electrodes. While Loi was working on the problem, IBM even patented the concept. “But there was a big problem in the IBM work: the polymers with thiols also attached to metallic nanotubes and included them in the transistors, which ruined them.”

Loi's solution was to reduce the thiol content of the polymers, with the assistance of polymer chemists from the University of Wuppertal. “What we have now shown is that this concept of bottom-up assembly works: by using polymers with a low concentration of thiols, we can selectively bring semiconducting nanotubes from a solution onto a circuit.” The sulphur-gold bond is strong, so the nanotubes are firmly fixed, staying put even after sonication in organic solvents.

The production process is simple: metallic patterns are deposited on a carrier, which is then dipped into a solution of carbon nanotubes. The electrodes are spaced to achieve proper alignment. “The tubes are some 500nm long, and we placed the electrodes for the transistors at intervals of 300nm. The next transistor is over 500nm.” This spacing limits the density of the transistors, but Loi is confident this could be increased with clever engineering.

“Over the last years, we have created a library of polymers that select semiconducting nanotubes and developed a better understanding of how the structure and composition of the polymers influences which carbon nanotubes they select,” says Loi. The result is a cheap and scalable production method for nanotube electronics.

So what is the future for this technology? “It is difficult to predict whether the industry will develop this idea, but we are working on improvements, and this will eventually bring the idea closer to the market,” Loi declares.

This story is adapted from material from the University of Groningen, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.