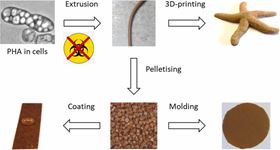

Schematic of fabrication of bacterial biomass-derived biocomposites.

Schematic of fabrication of bacterial biomass-derived biocomposites.Biodegradable polyesters made from whole bacteria could replace oil-based plastics in some applications but are currently too expensive. The cost of growing polyhydroxyalkanoates (PHA)-producing bacteria is high, as are the recovery and purification processes needed to turn PHA into useful materials. Efforts to reduce these costs have focused mainly on reducing the cost of feedstock by exploiting low-value by-products or waste for nutrients and fermentation. In contrast, researchers from Scion in New Zealand believe that similar or greater savings could be made by avoiding post-processing altogether and incorporating bacteria-derived PHA directly into biocomposites [Collet et al., Materials Today Communications 33 (2022) 104162, https://doi.org/10.1016/j.mtcomm.2022.104162].

Christophe Collet and his colleagues estimate that downstream processing of PHA-containing biomass from bacteria can account for 50% of overall production costs in terms of the energy input, solvents, and detergents required. Instead, the team from the government-owned research institute propose processing whole bacterial cells containing PHAs directly into biocomposites, avoiding extraction and purification stages.

The team extruded the biomass generated from the fermentation of three different strains of Gram-negative bacteria (Sphingobium scionense, Cupriavidus necator, and Pseudomonas putida) into a biocomposite without any additional purification. The whole of the cell, including cell-wall polysaccharides (sugars), proteins, polynucleotides, and phospholipids, are incorporated into the composite, serving as sustainable fillers. Each strain of bacteria produces a different PHA (PHB, PHBV, or mcl-PHA, respectively), which produces slightly different properties in the final material. The physical properties are comparable to traditional PHA-based biocomposites and can be molded or 3D-printed into structures or coated onto other materials. The researchers fabricated horticultural clips, which are used as plant supports in vineyards for example, and water-repellent coatings for outside or agricultural applications.

One potential downside to including the entire bacterial biomass in biocomposites is that some strains of bacteria generate endotoxins that are released when the cell breaks down. These biologically active molecules cause an immunological reaction from contact with the blood or food poisoning if ingested, as well as breathing difficulties if inhaled. Although the processing of PHAs into biocomposites significantly reduces the level of endotoxins, materials produced by these strains of bacteria would not be suitable for food or medical applications. Other Gram-negative bacteria known as Sphingomonads, however, do not yield endotoxins – because of the absence of lipopolysaccharides in their cell walls – and would be suitable for such applications.