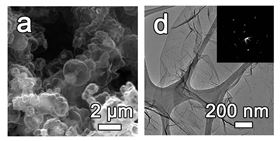

This is a scanning electron microscope image (left) and a transmission electron microscope image (right) of 3D printed graphene foam. The inset (right) shows a selected-area defraction pattern used to confirm that the material is graphene. Image: Yilun Li/Tour Group/Rice University.

This is a scanning electron microscope image (left) and a transmission electron microscope image (right) of 3D printed graphene foam. The inset (right) shows a selected-area defraction pattern used to confirm that the material is graphene. Image: Yilun Li/Tour Group/Rice University.Nanotechnologists from Rice University and Tianjin University in China have used 3D laser printing to fabricate centimeter-sized objects of atomically thin graphene. This research, which is reported in a paper in ACS Nano, could yield industrially useful quantities of bulk graphene.

"This study is a first of its kind," said Rice chemist James Tour, co-corresponding author of the paper. "We have shown how to make 3D graphene foams from non-graphene starting materials, and the method lends itself to being scaled to graphene foams for additive manufacturing applications with pore-size control."

Graphene, one of the most intensely-studied nanomaterials of the past decade, is a two-dimensional sheet of pure carbon that is both ultra-strong and conductive. Scientists hope to use graphene for everything from nanoelectronics and aircraft de-icers to batteries and bone implants. But most industrial applications would require bulk quantities of graphene in a 3D form, and scientists have struggled to find simple ways of creating bulk 3D graphene.

Then, in late 2016, researchers in Tour's lab began using lasers, powdered sugar and nickel to make 3D graphene foam. Earlier this year, they showed they could reinforce the foam with carbon nanotubes to produce a material they dubbed ‘3D rebar graphene’, which could retain its shape while supporting 3000 times its own weight (see Nanotube-reinforced graphene foam shows great strength). But making 3D rebar graphene was no simple task: it required a pre-fabricated 3D mold, a 1000°C chemical vapor deposition (CVD) process, and nearly three hours of heating and cooling.

In the latest study, a team from Tour's lab and the labs of Rice’s Jun Luo and Tianjin's Naiqin Zhao adapted a common 3D selective laser sintering technique to make fingertip-size blocks of graphene foam. The process doesn’t require any molds, uses powdered sugar and nickel powder as the starting materials, and is conducted at room temperature.

"This simple and efficient method does away with the need for both cold-press molds and high-temperature CVD treatment," said co-lead author Junwei Sha, a former visiting student in Tour's lab who is now a graduate student at Tianjin. "We should also be able to use this process to produce specific types of graphene foam like 3D printed rebar graphene as well as both nitrogen- and sulfur-doped graphene foam by changing the precursor powders."

Conventional extrusion-based 3-D printers create objects by squeezing melted plastic through a needle as they trace out two-dimensional patterns. By contrast, 3D selective laser sintering involves shining a laser beam onto a flat bed of powder, which melts or sinters into a solid form wherever it is touched by the laser. The beam is rastered, or moved back and forth, line-by-line to create a single two-dimensional slice of a larger object. Then a new layer of powder is laid over the top of that layer and the process is repeated to build up 3D objects from successive two-dimensional layers.

The new Rice process uses a commercially-available carbon dioxide laser. When this laser is shone onto the sugar and nickel powder, the sugar decomposes into a carbon source and the nickel acts as a catalyst. Graphene forms as the mixture cools once the laser has moved on to the next spot. Sha and colleagues conducted an exhaustive study to find the optimal amount of time and laser power for maximizing graphene production.

The foam created by the process is a low-density, 3D form of graphene with large pores that account for more than 99% of its volume. "The 3D graphene foams prepared by our method show promise for applications that require rapid prototyping and manufacturing of 3D carbon materials, including energy storage, damping and sound absorption," said co-lead author Yilun Li, a graduate student at Rice.

This story is adapted from material from Rice University, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.