Organic semiconducting materials have allured academic and industrial attention due to their pertinent utilization in future energy applications, flexible displays and solid state light sources. Modern optoelectronic devices based on inorganic and organic semiconducting materials suffer from internal energy losses and these losses convert into heat. The generated heat originates abeyant centers in the materials, which, further, become sources of heat generation. This generated heat invokes a chain reaction of creation of non-active centers in the semiconducting materials and further self multiplies. Therefore, thermal management of these optoelectronic devices is rather necessary for their future developments. Thermal management has been widely discussed in inorganic semiconductor based devices in comparison to their organic counterparts.

The first challenge for thermal management in organic optoelectronic devices is the temperature measurements of these devices. These devices are generally fabricated on substrates with poor thermal conductivity; therefore, the measurement of temperature is rather difficult by commercial techniques of mounting the devices on temperature sensing platforms. Raman spectroscopy and infrared (IR) thermography have been used to measure the device temperature in context of organic materials [1, 2]. Raman spectroscopy has disadvantages such as poor resolution of temperature and complexity of use. In comparison, IR-thermography has high sensitivity of temperature and comes with the ease of handling. Today, researchers are using IR-thermography to measure the temperature of OLED and studying effect of different heat sinks on the device temperature and stability.

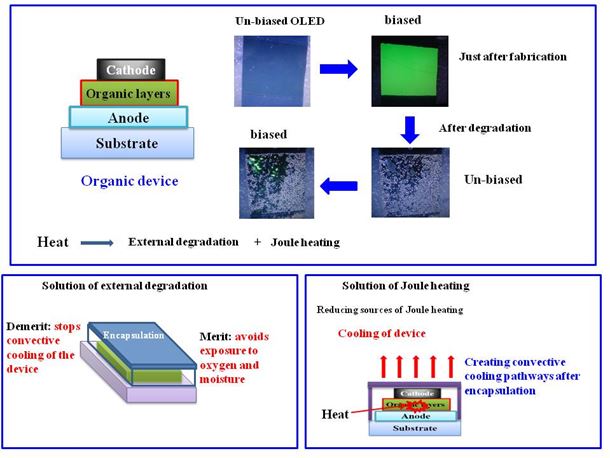

OLEDs have electrical and optical losses as the main sources of heat generation. Electrical losses include the resistive losses at cathode/organic interface and organic layers and optical losses include the non-radiative decay of excitons and light trapping due to wave guiding in ITO/organic layers and glass substrate. The generation of heat inside OLEDs can be reduced by decreasing the interface resistances and organic layer resistances. Recent studies revealed that about 97-98 % of the supplied power is lost due to the heat generation inside the device [2]. This indicates that enormous amount of heat is generated inside the device. This heat generation is reduced drastically by minimizing the interface resistances [3]. The probing of heat reduction has been efficiently performed by IR-thermography. This reduction of heat led to the enhanced performance of the device. OLEDs are fabricated on low thermal conductivity substrates; therefore, the generated heat cannot be efficiently extracted. Researcher have made some efforts on fabricating OLEDs on substrates of high thermal conductivity by changing the device structure and efficiently reduced the device temperature [4]. However, these methods are complicate in terms of device structure because they rely on fabrication of top – emitting OLEDs. Therefore, some new breakthroughs are required in the direction of thermal management of OLEDs and OPVs for their future applications. Future research on this topic will be on studying the effect of different techniques on reducing the heat generation as well as development of new methods to extract the generated heat from the device. Device reliability can be improved by both methods-reducing the generated heat has an upper hand because it also improves the efficiency. However, these losses cannot be reduced after a certain limit. Then, second way comes in picture i.e. improving the device reliability by proper heat dissipation. Efficient approaches towards this objective will be to incorporate heat sinks inside the device or in the encapsulation of the device.

Inorganic optoelectronic devices (PVs and LEDs) are now including thermal cooling panels for the proper heat dissipation. The road to commercialization of OPVs and OLEDs rely not only on the development of methods for their efficiency improvement, but, as well on the improvement towards the heat dissipation from the devices for their better life times. OLEDs are currently performing with efficiency more than 100 lm/W [5] and OPVs have already crossed an efficiency of 10 % [6]. Therefore, the future research should be oriented towards the thermal management in these devices. This will include the efficient extraction of heat from these devices and development of cooling panels for their long run.

Author

Dr. Priyanka Tyagi is a Senior Research Fellow in the Physics of Energy Harvesting Division at National Physical Laboratory, India and working in close collaboration with Dr. Ritu Srivastava of NPL and Prof. Suneet Tuli of Center for Applied Research in Electronics, Indian Institute of Technology, Delhi (India).

References

[1] H. Tsuji and Y. Furukawa, Chem Phys. Lett. 488 (2010) 206.

[2] X. Qi and S.R. Forrest, J. Appl. Phys. 110 (2011) 124516 .

[3] P Tyagi et al., Opt. Lett. 38, 3850 (2013).

[4] S. Chung et al., Appl. Phys. Lett. 94, (2009) 253302.

[5] S. Reineke et al., Nature 459, 234 (2009).

[6] See heliatek.com.

Watch our free presentations at the Thermal Analysis page here.