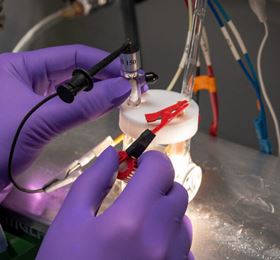

Guosong Zeng, a postdoctoral scholar at LBNL, testing the artificial photosynthesis device developed by Zetian Mi, a professor of Electrical and Computer Engineering at the University of Michigan. Image credit: Berkeley Lab.

Guosong Zeng, a postdoctoral scholar at LBNL, testing the artificial photosynthesis device developed by Zetian Mi, a professor of Electrical and Computer Engineering at the University of Michigan. Image credit: Berkeley Lab.Splitting water into hydrogen and oxygen using sunlight could prove the ultimate way to provide a clean, sustainable fuel for the modern world. Photoelectrochemical (PEC) systems capable of artificial photosynthesis rely on efficient and durable photoelectrodes. Now researchers think that they may have found the right material in the form of Si/GaN [Zeng et al., Nature Materials (2021), https://doi.org/s41563-021-00965-w].

One of the promising approaches to PEC water splitting relies on a photocathode that integrates a semiconductor with an electrocatalyst. The semiconductor acts as the collector of solar energy, while the electrocatalyst layer, which also serves as a protective layer, provides sites for chemical reaction to occur. The problem is that good photoabsorbers tend not to be durable and vice versa. Si, for example, is an excellent material for absorbing visible light but is not particularly robust, while GaN can act both as a protection layer and an electron transporter. Uniting the two materials in an electrode brings together their respective advantages. “Our previous results show that the Si/GaN/Pt photocathode can sustain high photocurrent density with high efficiency for more than 3,000 hours,” says Francesca Toma, staff scientist at LBNL, who led the effort with Tadashi Ogitsu of Lawrence Livermore National Laboratory and Zetian Mi of the University of Michigan. “We wanted to understand the origin of this stability,” she explains.

Not only can Si/GaN photocathodes support sustained hydrogen production in sunlight for over 150 h without the use of a catalyst but the materials have an unexpected advantage – the photocurrent density and onset potential improve during the first few hours of operation. This self-improvement arises, the researchers believe, because the GaN surface undergoes a chemical transformation that forms a protective gallium oxynitride layer over the Si and creates active catalytic sites for hydrogen evolution reactions to take place. The transformation simultaneously stabilizes the Si photocathodes.

“Our discovery is a real game-changer,” says Toma. “We discovered an unusual property in Si/GaN that enables it to become more efficient and stable over time.”

In the test system, a Si/GaN photocathode is used with an IrOx counter electrode in water reduction conditions. A photocurrent of over 100 mA/cm2 is generated during 150 h of operation under high illumination (3.5 suns), correlating to a 2–3 order of magnitude improvement in performance at the nanoscale. Scanning transmission electron microscopy (STEM) and angle-dependent X-ray photon spectroscopy (XPS) analysis, combined with density functional theory (DFT) simulations, confirmed the researchers’ hypothesis that a nanometer-thick layer of Ga, N, and O forms over the sidewall surfaces of the photocatalyst.

The researchers believe that the findings provide an insight into how protective layers provide stability in PEC reactions and offer opportunities for designing more durable and efficient photoelectrodes. Toma and her team now plan to test the Si/GaN artificial photosynthesis devices in real world conditions.

“We’ve been working on this material for over 10 years – we know it’s stable and efficient. But this [study] helped to identify the fundamental mechanisms behind why it gets more robust and efficient instead of degrading,” adds Zetian Mi of the University of Michigan. “Si and GaN are the two most produced semiconductors in the world. Their scalable manufacturing and low cost, high throughput production has been well established, which will greatly accelerate the practical application of our artificial photosynthesis devices.”

This article was first published in Nano Today 38 (2021) 101172.