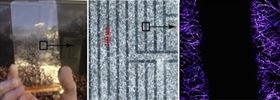

Multi-touch silver nanowire sensors.

Multi-touch silver nanowire sensors.Networks of tiny silver nanowires could replace the transparent electrodes currently used in smart phone and tablet sensors, according to researchers.

The appeal of smart phones and tablets hinges on their responsive touch screens, which rely on transparent indium tin oxide (ITO) electrodes as part of multiplex sensors. But indium is scarce, leading to unpredictable ITO costs. Moreover, fabricating good quality ITO films requires high temperatures, so alternative materials could be more efficient as well as cheaper.

Silver nanowire (AgNW) films are particularly promising because they can be fabricated economically from a readily available abundant metal and are flexible enough to enable larger screens or even electronic newspapers in the future. Now researchers from the Universities of Surrey and Sussex have shown that the industrial techniques used to fabricate the sensors in smart phones and tablets could just as easily incorporate AgNWs instead of ITO [Cann et al., Materials Today Communications 7 (2016) 42].

“Our aim was to show how easily nanowire films could slot into sensor manufacturing,” explains first author Maria Cann of the University of Surrey and M-Solv. “Using industry techniques traditionally employed to pattern ITO, we made a multiplex sensor with the touch sensitivity equivalent to a commercially available smart phone.”

The team spray deposited AgNWs of 25 nm and 60 nm diameter onto one side of a glass slide to make a conductive surface. The electrodes were then fashioned by laser ablating away selected areas of the conductive film. The approach allows the intricate circuitry of the electrodes to be cut into the film, producing tracks as narrow as 70 microns.

“This is, by a long way, the highest resolution sensor produced by spray deposited nanowires,” says Alan B. Dalton of the University of Sussex. “The laser ablation process is also very cost effective and, as it is already used in the mass production of sensors, would slot straight into a manufacturing process.”

The researchers found that longer, smaller diameter nanowires created the most transparent and best performing sensors. Even though the AgNW sensors were fabricated in a lab, they compete with and even outperform some aspects of traditional ITO sensors, according to the researchers.

This simple approach to fabricating transparent touch-sensitive sensors could cut manufacturing costs, by reducing material and temperature requirements, as well as the weight of electronic devices.

“The flexibility of nanowire films is particularly useful to make flexible electronic devices and wearable electronics,” adds Dalton. “The spray process also opens up the possibility of building sensors in to 3D formed devices.”

The team are now exploring how the nanowire films behave in flexible devices and under different environmental conditions.