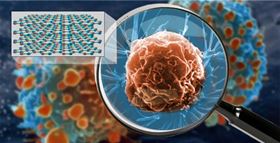

A new hyperlens crystal is capable of resolving details as small as a virus on the surface of living cells. The cut-out (top left) shows the atomic structure of the hexagonal boron nitride crystal. Image: Keith Wood, Vanderbilt University.

A new hyperlens crystal is capable of resolving details as small as a virus on the surface of living cells. The cut-out (top left) shows the atomic structure of the hexagonal boron nitride crystal. Image: Keith Wood, Vanderbilt University.Just imagine an optical lens so powerful that it can image features the size of a small virus on the surface of a living cell in its natural environment.

Construction of instruments with this capability is now possible thanks to a fundamental advance in the quality of an optical material used in hyperlensing, which is a method for creating lenses that can resolve objects much smaller than the wavelength of light. This achievement was reported by a team of researchers led by Joshua Caldwell, associate professor of mechanical engineering at Vanderbilt University, in a paper in Nature Materials.

The optical material involved is hexagonal boron nitride (hBN), a natural crystal with hyperlensing properties. The best previously reported resolution using hBN was of an object about 36 times smaller than the infrared wavelength used to illuminate it: about the size of the smallest bacteria. This new paper describes improvements in the quality of the crystal that can enhance its potential imaging capability by about a factor of 10.

The researchers achieved this enhancement by making hBN crystals using isotopically purified boron. Natural boron is made up of two isotopes that differ in weight by about 10%, which significantly degrades the crystal's optical properties in the infrared.

"We have demonstrated that the inherent efficiency limitations of hyperlenses can be overcome through isotopic engineering," said team member Alexander Giles, research physicist at the US Naval Research Laboratory. "Controlling and manipulating light at nanoscale dimensions is notoriously difficult and inefficient. Our work provides a new path forward for the next generation of materials and devices."

Researchers from the University of California, the University of San Diego, Kansas State University, Oak Ridge National Laboratory and Columbia University also contributed to the study. They calculate that a lens made from their purified crystal can in principle capture images of objects as small as 30nm in size.

Over the years, scientists have developed many instruments capable of producing images with nanoscale resolution, such as electron microscopes and atomic-force microscopes. However, these instruments are incompatible with living organisms. This is because they either operate under a high vacuum, expose samples to harmful levels of radiation, require lethal sample preparation techniques like freeze drying or remove samples from their natural, solution-based environment.

The primary reason for developing hyperlenses is the prospect that they can produce nanoscale-resolution images of living cells in their natural environments using low-energy light such as infrared that does not harm the cells. Another advantage of using infrared light is that it can provide spectroscopic information about the objects it images, offering a means to 'fingerprint' the material. These capabilities could be particularly useful for biological and medical science, and for studying nanoscale communications and optical components.

The physics of hyperlenses is quite complex. The level of detail that optical microscopes can image is limited by the wavelength of light used to illuminate the object and the index of refraction of the lens material. When combined with other factors, such as lens aperture, distance from the object to the lens and the refractive index of the object under observation, this translates to a typical optical limit of about one half the wavelength used for illumination.

At the infrared wavelengths used in this study, the ‘diffraction limit’ is about 3250nm. This limit can be surpassed with hBN due to its ability to support surface phonon polaritons, hybrid particles made up of photons of light coupling with vibrating, charged atoms in the crystal with wavelengths much shorter than the incident light.

In the past, the problem with using polaritons in this fashion has been the rapidity with which they dissipate. Using hBN crystals made from 99% isotopically pure boron, the researchers have measured a dramatic reduction in optical losses compared to natural crystals. This increases the polariton's lifetime three-fold and allows them to travel three times the distance, which translates into a significant improvement in imaging resolution. Theoretical analysis by the researchers suggests that another factor of 10 improvement is possible.

"Currently, we have been testing very small flakes of purified hBN," said Caldwell. "We think that we will see even further improvements with larger crystals."

In 1654, Anton van Leeuwenhoek used one of the first handcrafted microscopes to discover the previously unknown world of microscopic life. This latest advance in hyperlens development is a significant step toward taking van Leeuwenhoek's discovery to a whole new level, one which will allow biologists to directly observe cellular processes in action, like viruses invading cells or immune cells attacking foreign invaders.

This story is adapted from material from Vanderbilt University, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.