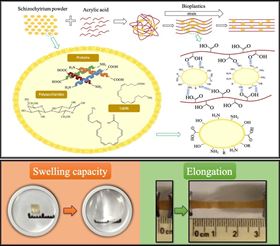

The mechanism of bio-based polymers formation and the new hybrid materials' outstanding swelling and viscoelastic properties. Image courtesy of Gabriela Palestino, Universidad Autónoma de San Luis Potosí.

The mechanism of bio-based polymers formation and the new hybrid materials' outstanding swelling and viscoelastic properties. Image courtesy of Gabriela Palestino, Universidad Autónoma de San Luis Potosí.Researchers from Universidad Autónoma de San Luis Potosí in Mexico have synthesized a novel bio-based polymer using poly(acrylic acid) (PAA) and the microalgae Schizochytrium specie [Olvera-Sosa et al., Materials Today Communications 26 (2021) 102029, https://doi.org/10.1016/j.mtcomm.2021.102029]. Both the whole of the microorganism and the insoluble cell wall were used in various amounts to produce biopolymers with different physical, chemical, mechanical and thermal properties, which the researchers believe could offer a sustainable alternative to synthetic polymers produced from fossil fuels.

“Recent advances in composite and polymeric formulations have focused on developing novel bio-based polymers, which are compounds or derivatives from biological products. These materials provide suitable biodegradable alternatives to replace conventional plastics, says Gabriela Palestino, who led the work.

Synthetic polymers are used in almost every aspect of modern life because of the remarkable variety of physical properties and attributes that can be achieved. But the very robustness and inertness that is so useful in applications makes synthetic polymers very difficult to recycle or dispose of. Every year, 150 million tons of fossil fuels are consumed to produce 140 million tons of synthetic polymers used worldwide, with 50 million tons of single-use plastic accumulating in landfills and oceans. The scale of the problem demands a more sustainable, bio-based, biodegradable or recyclable alternative as a matter of urgency.

Biomass from a variety of sources, most recently microalgae, is being explored as raw materials for polymers. The microalga Schizochytrium sp. is already well-used industrially as a food and pharmaceutical additive because of its high content of polyunsaturated fatty acids. Now Palestino and her colleagues have used this microorganism to synthesize bio-based polymers in a simple, low-cost procedure. The researchers produced two different polymers using either the whole organism or just insoluble fatty acids derived from the cell walls.

“The ability to tune the materials’ properties [offers] the possibility of using them in a broad range of applications, including biomedicine and materials engineering,” says Palestino.

The resulting biopolymers show contrasting thermal and elastic properties that depend on the amount of biomass or cell wall material. Highly viscous and elastic polymeric material with the propensity to swell is produced from the entire microalgae, while using cell wall material produces a much more rigid polymer.

The researchers believe their tailorable bio-based polymers could offer a sustainable alternative to conventional petrochemical-based plastics with real potential on an industrial scale. Microalgae are cheap, easy and quick to grow compared with other sources of biomass.

“[Our bio-based polymers] are candidates for biomedicine applications such as tissue engineering, drug delivery systems, or the production of biodegradable engineering products such as plastic bags and bottles,” points out Palestino.