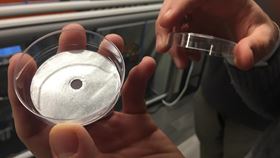

A sample of the perfluorinated sulfonic acid ionomer developed at NYU Tandon. One part of the copolymer conducts ions, while the other is highly permeable to oxygen. Photo: NYU Tandon School of Engineering.

A sample of the perfluorinated sulfonic acid ionomer developed at NYU Tandon. One part of the copolymer conducts ions, while the other is highly permeable to oxygen. Photo: NYU Tandon School of Engineering.Renewed investments in hydrogen fuel cell technologies and infrastructure by companies like Amazon, nations like China, and automakers like Toyota, Honda and Hyundai are sparking sales and fresh interest in the vast possibilities of polymer-electrolyte fuel cells. This fresh interest could revolutionize transportation and fill streets with vehicles whose only exhaust fumes are water vapor.

But that vision of clean, green cars and trucks is stymied by the need not only for massive infrastructure investment, but also for more efficient processes in the fuel cells themselves. Innovations that lower the cost of production – meaning lower prices – and that open the door to more vehicle segments, including performance cars, could drive greater adoption.

A team of researchers at the NYU Tandon School of Engineering and the Lawrence Berkeley National Laboratory has now created a novel polymeric material with the potential for solving both these problems. The researchers include Miguel Modestino, professor of chemical and biomolecular engineering at NYU Tandon, and Yoshi Okamoto, a professor of chemical engineering and director of the Polymer Research Institute at NYU Tandon.

Their hybrid material can deliver copious amounts of oxygen from the atmosphere to the cell's electrode reaction sites – generating more power – while also reducing the amount of expensive materials like platinum needed in fuel cells, potentially solving a major industry challenge. They describe this material in a paper in the Journal of the American Chemical Society.

Hydrogen fuel cells comprise an anode and a cathode separated by an electrolyte membrane. Electricity is produced as a result of hydrogen being split into electrons and protons at the anode. Ion-conducting polymers (ionomers) are used to transfer the protons to the cathode, where they combine with oxygen from the air to produce water, while the electrons are sent round an external circuit to generate electricity.

Current, commercially available ionomers are typically perfluorinated sulfonic acid (PFSA) polymers, which comprise a linear chainlike backbone composed of polytetrafluoroethylene (PTFE) matrix and pendant sulfonic-acid groups attached to the PTFE backbone that impart ion conductivity. While this complex combination, molecularly similar to Teflon, confers high mechanical strength, research shows that it suffers from low oxygen permeability, leading to significant energy losses in fuel cells.

The researchers solved several problems at once by swapping the linear PTFE polymer chains for a bulky fluorinated chain, creating a hybrid material that comprises an ion conducting polymer and a highly permeable matrix. This added more free volume to the matrix, vastly enhancing its ability to transport oxygen.

"We've created a novel copolymer – two components bound together. One part conducts ions, and the other is highly permeable to oxygen," explains Modestino. "Okamoto had been working on highly permeable polymers for gas separation processes. When I joined NYU Tandon, we realized that the polymers that he had developed could be adapted to improve fuel cells."

This story is adapted from material from the NYU Tandon School of Engineering, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.