4D direct laser writing (DLW) process and umbrella-like hydrogel structure.

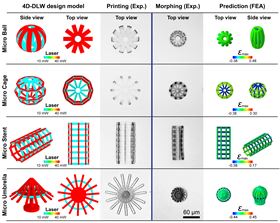

4D direct laser writing (DLW) process and umbrella-like hydrogel structure. Illustration and photos of different DLW structures and their transformations into 3D architectures.

Illustration and photos of different DLW structures and their transformations into 3D architectures.Tiny micromachines able to respond and interact with their environment could be a boon for minimally invasive surgery, cell manipulation, and other biomedical applications. Now researchers from Peking University and The Chinese University of Hong Kong have developed a direct laser writing approach that can print such shape-changing micromachines in a single step.

“Scientists and engineers have long dreamt of intelligent micromachines capable of handling complex or tough tasks by switching their shape or function in response to external stimuli,” says Tian-Yun Huang, corresponding author on the study. “In recent years, thanks to the development of smart materials and fabrication technology, some reconfigurable systems have been constructed, but their shape-morphing performance has a limited degree of freedom, especially at small scales.”

Huang and his colleagues have developed a new nanofabrication technique that could offer a step forward in the construction of active three-dimensional (3D) structures at small scales. The technique uses direct laser writing to print layers of stimulus-responsive hydrogels, which build up into 3D structures. The process uses two-photon polymerization whereby ultrafast laser pulses crosslink smart hydrogels into more robust materials. Crosslinking only occurs in the immediate vicinity of the laser beam focus point, so sub-micron features are possible, and density increases with exposure time, so the stiffness of the material can be readily controlled.

“To achieve large deformations, crosslinking densities should be set at relatively low levels, which, however, makes polymers too soft for freestanding 3D architectures,” points out Huang, “but increasing the crosslinking density reduces the microstructure deformability.”

There is an inevitable trade-off between deformability and structural complexity, but the new approach allows the construction of complex, reconfigurable micromachines including cages, stents, and lantern-like structures, which display excellent deformation characteristics, transforming rapidly and reversibly from 3D-to-3D shape in response to external stimuli. The researchers add pH-responsive carboxylic groups to the hydrogels, which accept or release protons in acid or alkali conditions, respectively, triggering shrinking or swelling. The micromachines respond to external stimuli in a matter of seconds, faster than many other similar systems, claim the researchers. Printed microballs, for example, transform in shape completely and immediately at a pH of 8.5 or in response to chemical solvents and temperature. The team also created an umbrella-like folding structure that opens and closes in response to pH.

“Micromachines that can morph into multiple functional conformations in response to external stimuli, such as light, heat, pH, and magnetic field, represent a promising strategy in a wide variety of engineering applications,” says Huang.

Biomedical applications such as vascular stents and artificial cardiac valves, as well as targeted drug carriers are attractive possibilities. Moreover, points out Huang, more complex systems could be built by tacking micromachine building blocks together.

Jin et al., Materials Today (2019), https://doi.org/10.1016/j.mattod.2019.06.002