Capturing carbon dioxide, especially at the most significant industrial sources such as power plants, could significantly help limit global warming. Elsevier 2018

Capturing carbon dioxide, especially at the most significant industrial sources such as power plants, could significantly help limit global warming. Elsevier 2018It may be feasible to capture carbon dioxide emissions on a large scale while putting the captured carbon to good use.

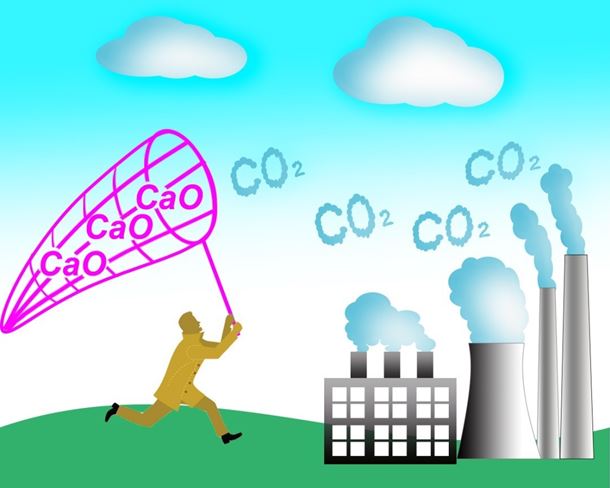

Capturing carbon dioxide (CO2) rather than releasing it into the atmosphere is one of the most promising strategies for helping to meet the aim of the ‘Paris Agreement’ to limit the average increase in global temperatures to 2 degrees Celsius by the end of the century. Researchers in the UK, China and Australia review one carbon-capturing possibility – a combination of CO2 with calcium oxide (CaO) to form calcium carbonate (CaCO3) – in the journal Materials Today Sustainability.

“Considerable efforts are being devoted to developing more efficient and economical CO2 capture technologies,” says lead author Hongman Sun of Queen’s University Belfast and the University of Hull in the UK. Reflecting the global significance of the issue, Sun collaborated on the review with co-authors from Hebei University of Technology in China, China University of Petroleum and the University of Sydney in Australia.

Calcium carbonate, some forms of which we know as chalk and marble, could be a good product to keep CO2 reliably locked away in a very stable form. It also has economic value as a material used in several industries, including construction and paper-making. But more interest has focused on cyclical or ‘looping’ processes, which later release the captured CO2 for direct storage or make use of it in some other way.

The authors pay particular attention to a process in which the captured CO2 is converted to methane (CH4) – the fuel we know as natural gas – regenerating the calcium oxide to enter the cycle again. Thus CO2 in the atmosphere, released by fuel burning, could be captured to generate new fuel in a way that, overall, would be carbon-neutral. There are many unknowns, however, in understanding the chemical conditions and reaction mechanisms that could most effectively use calcium oxide to trap atmospheric CO2 and also promote the looping reaction.

“Our review provides a comprehensive summary of the current understanding of carbon capture processes, and summarises effective approaches towards enhancing the performance of calcium oxide-based materials,” says Sun.

One major problem has been the tendency of the calcium oxide to coalesce, a process known as sintering, after a number of cycles of CO2 capture and release. While reviewing understanding of the chemical mechanism of the cyclic reactions, the authors examine options for overcoming the sintering issue.

One promising avenue is to use synthetic calcium oxide-based adsorbents, which are blended with other materials such as oxides containing both calcium and aluminium.

Pilot-scale experiments have demonstrated the potential of such a procedure, but technical improvements, most likely driven by improved understanding of the chemistry involved, are still needed before large-scale application will become feasible.

“Much of our own research work is focused on developing carbon capture and utilisation (CCU) technologies,” says Sun. The authors point out that this has several economic and environmental advantages over the simpler carbon capture and storage (CCS) options, in which the CO2 is stored in some form rather than being exploited as a useful chemical resource.

Article details:

Sun, H. et al.: “Progress in the development and application of CaO-based adsorbents for CO2 capture – a review,” Materials Today Sustainability (2018).