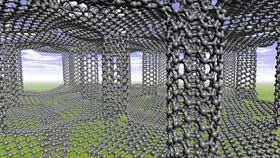

This image shows the junctions between sheets of graphene and the nanotubes that connect them in pillared graphene. Image: Lei Tao/Rice University.

This image shows the junctions between sheets of graphene and the nanotubes that connect them in pillared graphene. Image: Lei Tao/Rice University.Pillared graphene would transfer heat better if the theoretical material had a few asymmetric junctions that caused wrinkles, according to engineers at Rice University.

Rice materials scientist Rouzbeh Shahsavari and alumnus Navid Sakhavand began by building atom-level computer models of pillared graphene – sheets of graphene connected by covalently bonded carbon nanotubes – to discover their strength and electrical properties, as well as their thermal conductivity.

In this new study, they found that manipulating the joints between the nanotubes and graphene has a significant impact on the material's ability to direct heat, which could prove important as electronic devices shrink and require more sophisticated heat sinks. They report their findings in a paper in ACS Applied Materials and Interfaces.

Researchers who study or try to fabricate pillared graphene have primarily focused on two characteristics of the theoretical material: the length of the pillars and their distance from each other. The new study suggests that a third parameter – the nature of the junction between the graphene and nanotubes – should also be considered.

A seamless connection between flat graphene, the atom-thick form of carbon, and round nanotubes requires adjustments to their characteristic six-member carbon rings. The simplest way is to give half the rings at the junction an extra atom. Six seven-member rings alternating with six six-member rings allow the sheet to make a 90° turn to become a tube.

But that's not the optimal configuration for heat transport, according to the Rice team. It found that replacing six heptagons with three octagons would facilitate the turn while slightly stressing the graphene. That would wrinkle the graphene sheets' top and bottom while not significantly changing transport at the junctions.

The researchers intuitively expected the wrinkles to lower thermal transport and were surprised to find that thermal transport across the ‘in-plane’ graphene actually became faster with wrinkles. They determined that having fewer rings in the junctions between nanotubes and graphene meant less scattering of heat-carrying phonons, which kept them onboard for the bumpy ride.

Measured along the longest plane, models with the octagons were nearly 20% better at transporting phonons than those without. "Our results show that subtle features such as this junction configuration have a significant impact on thermal transport," said Shahsavari, an assistant professor of civil and environmental engineering and of materials science and nanoengineering. "Given the current needs in thermal management and device miniaturization in many nano- and microelectronics, this study provides a new degree of freedom to play and improve thermal transport."

The researchers thought phonon transport through the nanotubes, which they already knew was slower than in graphene, might be slower still under the influence of the octagons, but the altered interface didn't appear to have a significant effect.

"The reason lies in the geometry," Shahsavari explained. "The lower the number of non-hexagonal rings in the junction (for example, three octagons versus six heptagons), the lower the number of undesirable rings and thus lower phonon scattering and improved thermal transport." Because the junctions can adopt many different geometries depending on the radius and chirality of the nanotube, there are many other potential configurations to be modeled, he said.

This story is adapted from material from Rice University, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.