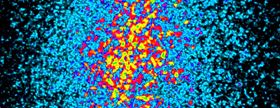

A speckle pattern typical of the sort produced by the LCLS's detectors. Image: Joshua Turner.

A speckle pattern typical of the sort produced by the LCLS's detectors. Image: Joshua Turner.X-rays can be used like a superfast, atomic-resolution camera. If researchers shoot a pair of X-ray pulses just moments apart, they can get atomic-resolution snapshots of a system at two points in time. Comparing these snapshots shows how a material fluctuates within a tiny fraction of a second, which can help in the design of future generations of super-fast computers, communication devices and other technologies.

Resolving the information in these X-ray snapshots, however, is difficult and time intensive. So a team led by Joshua Turner, a lead scientist at the US Department of Energy’s SLAC National Accelerator Center and Stanford University, turned to artificial intelligence to automate this process. Their novel machine learning method, reported in a paper in Structural Dynamics, accelerates this X-ray probing technique, and extends it to previously inaccessible materials.

“The most exciting thing to me is that we can now access a different range of measurements, which we couldn't before,” Turner said.

When studying a material using this two-pulse technique, the X-rays scatter off the material and are usually detected one photon at a time by a detector, producing a speckle pattern – a blotchy image that represents the precise configuration of the sample at one instant in time. Researchers then compare the speckle patterns from each pair of pulses to reveal fluctuations in the sample.

“However, every photon creates an explosion of electrical charge on the detector,” Turner said. “If there are too many photons, these charge clouds merge together to create an unrecognizable blob.” This cloud of noise means the researchers must collect tons of scattering data to yield a clear understanding of the speckle pattern.

“You need a lot of data to work out what’s happening in the system,” said Sathya Chitturi, a PhD student at Stanford University, who is advised by Turner and co-author Mike Dunne, director of the Linac Coherent Light Source (LCLS) X-ray laser at SLAC.

With conventional methods, all of the data had to be collected first then analyzed using models that estimate how the photons bunch together at the detector – a lengthy process to understand the speckle patterns. The novel machine-learning method, on the other hand, uses the raw detector image of scattered photons to directly extract fluctuation information. This new method is 10 times faster on its own and 100 times faster when combined with improved hardware, allowing data analysis in closer to real time.

Part of the success of the new method came from the efforts of co-author Nicolas Burdet, an associate staff scientist at SLAC, who developed a simulator that produced data with which to train the machine-learning model. Through this training, the algorithm was able to learn how the charge clouds merge, and untangle how many photons hit the detector per blob and per pulse pair. The model proved accurate even under very blobby conditions.

The model can extract information for a range of materials that have been difficult to study because X-rays scatter off them too weakly for detection, such as high-temperature superconductors and quantum spin liquids. Chitturi said the new method could also be applied to other, non-quantum materials, including colloids, alloys and glasses.

According to Turner, this research should be a help for the LCLS-II upgrade, which will allow researchers to collect up to a million images, or a few terabytes of data, per second, compared to about a hundred images a second for the current LCLS.

“At SLAC we’re excited about this upgrade but have also been kind of worried if we can handle this amount of data,” Turner said. But the team has now confirmed that their new machine-learning method should be fast enough to deal with all that data. “This new algorithm will really help.”

The speed boost offered by artificial intelligence also promises to alter the experimental process itself. Instead of making decisions after data collection and analysis, researchers will be able to analyze data and make changes during data collection, which should save time and money during the experiment. It will also allow the researchers to spot surprises and redirect their experiments in real time to investigate unexpected phenomena.

“This method can let you explore more of the materials science you're interested in and maximize scientific impact by letting you make decisions at different points along your experiment about changes in experimental variables such as temperature, magnetic field and material composition,” Chitturi said.

This story is adapted from material from SLAC National Accelerator Center, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.