An international team of researchers have developed the first true supermirrors in the mid-infrared (MIR) spectral region, a breakthrough that could enhance applications such as optical spectroscopy for environmental sensing, laser cutting and welding for manufacturing, as well as improve climate and biofuel research based on precision trace gas sensing.

The ultimate goal of high-performance mirror research is to achieve coatings with perfect reflectivity and here, as reported in Nature Communications [Truong et al. Nat. Commun. (2023) DOI: 10.1038/s41467-023-43367-z], the first true MIR supermirrors were demonstrated. The new mirrors lose only 8 photons out of 1 million, a reflectivity of 99.99923%, greatly improving on the best MIR mirrors to date, which lose roughly 1 out of every 10,000 photons.

In the visible wavelength range, advanced metallic mirrors usually attain reflectivities as high as 99%, which means 1 photon is lost for every 99 reflected. Although this appears effective, in the near-infrared region mirror coatings have already demonstrated 99.9997% reflectivity (ie, losing only 3 photons out of 1 million reflected). Much research has therefore gone into extending this into the MIR, to advance trace gas sensing tasks related to climate change and biofuels, and also in applications such as laser machining and nanofabrication.

To achieve such extreme reflectivities, a new paradigm in coatings was demonstrated by combining conventional thin-film coating techniques with innovative semiconductor materials and processes to overcome the material constraints in the MIR region. These mirrors leverage the purity and structural quality of molecular beam epitaxy, which is used to manufacture a range of semiconductor devices, to produce monocrystalline GaAs/AlGaAs multilayers with negligible absorption and scatter. This material is then turned into high-performance mirrors using advanced microfabrication techniques.

In helping to advance the state of the art in MIR cavity mirrors, these all-crystalline and crystalline-amorphous hybrid supermirrors are the first that permit ultrahigh-finesse cavities in the MIR spectral region. In this, they also permit spectroscopy at unprecedented sensitivity and specificity.

As researcher Oliver Heckl told Materials Today, “Crystalline growth at the needed quality is limited to a certain overall thickness, while materials commonly used in amorphous coatings face an increase in absorption when moving to longer wavelengths. Hence, the hybrid coatings are a clever combination of the two technologies that leverages the benefits of both platforms."

The new supermirrors demonstrate it is possible to successfully integrate amorphous and crystalline thin film layers in a single platform, and to scale them to even longer wavelengths for applications such as precision spectroscopy and laser-based manufacturing, as well as extreme ultraviolet lithography. However, the mirror manufacturing technique employed still needs to be improved to allow the realization of high-performance and low-loss mirrors for these longer wavelengths.

“The hybrid coatings are a clever combination of the two technologies that leverages the benefits of both platforms.”Oliver Heckl

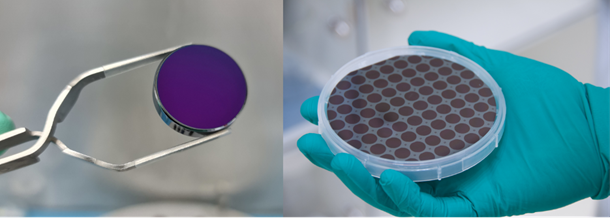

Photographs of the component coatings for MIR supermirrors; left: a one-inch diameter silicon substrate coated with a conventionally deposited interference coating (c) 2022 Valentin Wittwer; right: a patterned four-inch GaAs wafer with monocrystalline GaAs/AlGaAs dies that will eventually be fusion-bonded onto the coated silicon substrates (c) 2018 Georg Winkler

Photographs of the component coatings for MIR supermirrors; left: a one-inch diameter silicon substrate coated with a conventionally deposited interference coating (c) 2022 Valentin Wittwer; right: a patterned four-inch GaAs wafer with monocrystalline GaAs/AlGaAs dies that will eventually be fusion-bonded onto the coated silicon substrates (c) 2018 Georg Winkler