Understanding roughness at tiny scales allowed researchers to understand the mechanics of how soft materials adhere to rough surfaces. Image: University of Akron College of Polymer Science and Polymer Engineering.

Understanding roughness at tiny scales allowed researchers to understand the mechanics of how soft materials adhere to rough surfaces. Image: University of Akron College of Polymer Science and Polymer Engineering.Tires gripping the road, non-slip shoes preventing falls, a hand picking up a pen, a gecko climbing a wall: all depend on a soft surface adhering to and releasing from a hard surface, a common yet incompletely understood interaction. Now, in a paper in the Proceedings of the National Academy of Sciences, a team of researchers from the US and Germany reveals the missing link between soft surface adhesion and the roughness of the hard surface it touches.

Tevis Jacobs, assistant professor of mechanical engineering and materials science at the University of Pittsburgh's Swanson School of Engineering, and Ali Dhinojwala, interim dean and professor of polymer science at The University of Akron's College of Polymer Science and Polymer Engineering, used in situ microscopic measurements of contact size to unlock the fundamental physics of how roughness affects soft material adhesion.

"A gecko running up a vertical wall is an excellent example of how nature has developed a solution to stick to rough surfaces," says Dhinojwala. "The key to achieve this adhesion on rough surface is molecular contact. Soft material can conform to rough surfaces and create the molecular contact necessary to stick well. We need a fundamental understanding of the parameters that control adhesion to rough surfaces and the underlying physics."

There are two different parts of this adhesion process: what happens when the molecular contact is established and what happens when it is terminated. Previous theories have proposed how roughness affects the first half of the process, but offer no insight into the second half. This problem is called ‘adhesion hysteresis’, meaning the soft surface behaves differently when it encounters the rough surface than when it is pulled away.

One way to think about adhesion hysteresis is in terms of a small rubber ball. Pressing the ball down against a hard surface expands the area of contact; letting go will cause the area to shrink again, but not in a predictable, symmetrical way. The current discovery marks the first model of rough adhesion that can predict both parts of the process.

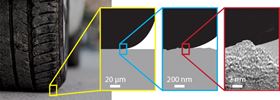

The key to this foundational discovery is looking very closely at the rough surface itself. "People have been measuring roughness for a hundred years, but conventional techniques can't see the small detail," says Jacobs. "We zoomed in, combining multiple techniques, to measure roughness on top of roughness on top of roughness. The texture goes down to the atomic scale for many surfaces."

The group developed a new approach using an electron microscope to measure roughness down to below the scale of a nanometer. One of the surfaces in this study appeared far smoother than two others when measured using conventional techniques. When measured down to the atomic scale, however, it proved to be the roughest of all, with the small-scale roughness creating a lot more surface area for the soft material to grip. This detailed understanding of the rough surface was the missing link that explained the surfaces' adhesion behavior.

"Our research answered an important question, but in another sense, it opened up a new line of inquiry," says Jacobs. "There are a lot of interesting questions about what it really means for surfaces to be 'in contact' and how to link what is happening at the atomic-scale to what we observe in full-size, real-world contacts. And we're excited to continue answering them."

This story is adapted from material from the University of Pittsburgh, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.