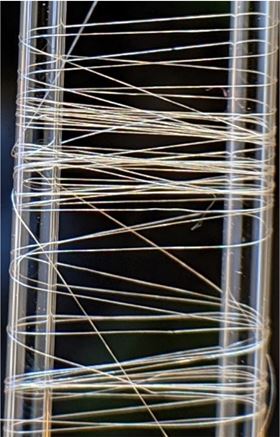

The new artificial spider silk, which is spun from amyloid silk hybrid proteins produced by engineered bacteria. Photo: Washington University in St. Louis/Jingyao Li.

The new artificial spider silk, which is spun from amyloid silk hybrid proteins produced by engineered bacteria. Photo: Washington University in St. Louis/Jingyao Li.Spider silk is said to be one of the strongest, toughest materials on Earth. Now, engineers at Washington University in St. Louis have used amyloid silk hybrid proteins to create fibers that are stronger and tougher than some natural spider silks. The engineers report their advance in a paper in ACS Nano.

To be precise, the artificial silk – dubbed 'polymeric amyloid' fiber – was not technically produced by researchers, but by bacteria that were genetically engineered in the lab of Fuzhong Zhang, a professor in the Department of Energy, Environmental & Chemical Engineering.

Zhang has worked with spider silk before. In 2018, his lab engineered bacteria that could produce a recombinant spider silk that matched its natural counterparts in all the main mechanical properties. "After our previous work, I wondered if we could create something better than spider silk using our synthetic biology platform," Zhang said.

The research team, which includes first author Jingyao Li, a PhD student in Zhang's lab, modified the amino acid sequence of spider silk proteins to introduce new properties, while keeping some of the attractive features of spider silk.

A problem associated with the original recombinant spider silk fiber was the need to create β-nanocrystals, a main component of natural spider silk, which contributes to its strength. "Spiders have figured out how to spin fibers with a desirable amount of nanocrystals," Zhang said. "But when humans use artificial spinning processes, the amount of nanocrystals in a synthetic silk fiber is often lower than its natural counterpart."

To solve this problem, the engineers redesigned the silk sequence by introducing amyloid sequences with a high tendency to form β-nanocrystals. This involved creating different polymeric amyloid proteins using three well-studied amyloid sequences as representatives.

The resulting proteins had less repetitive amino acid sequences than spider silk, making them easier to be produced by engineered bacteria. Ultimately, the bacteria produced a hybrid polymeric amyloid protein with 128 repeating units.

The longer the protein, the stronger and tougher the resulting fiber. The 128-repeat proteins produced a fiber with gigapascal strength (a measure of how much force is needed to break a fiber of fixed diameter), making it stronger than common steel. The fibers' toughness (a measure of how much energy is needed to break a fiber) is higher than Kevlar and all previous recombinant silk fibers. Its strength and toughness are even higher than some reported natural spider silk fibers.

In collaboration with Young-Shin Jun, professor in the Department of Energy, Environmental & Chemical Engineering, and her PhD student Yaguang Zhu, the team confirmed that the high mechanical properties of the polymeric amyloid fibers indeed come from the enhanced amount of β-nanocrystals.

These new proteins and the resulting fibers are not the end of the story for high-performance synthetic fibers in the Zhang lab. He and his team are just getting started. "This demonstrates that we can engineer biology to produce materials that beat the best material in nature," Zhang said.

This story is adapted from material from Washington University in St. Louis, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.