Because of current environmental concerns and stricter regulations worldwide, the design of engineering materials using ecologically-friendly and sustainable manufacturing routes is very much en-vogue. As a result, bio-composites, which are derived from the combination of natural fibers with a plastic matrix, have found applications in the automotive and packaging industries. Bio-composites, however, all exhibit a limited long-term structural and functional stability resulting from the poor interfacial affinity/compatibility between the hydrophilic natural fiber and the hydrophobic plastic, which impedes their use for a number of applications.

A team of researchers from the Institute for Frontier Materials at Deakin University and the CSIRO, recently report in European Polymer Journal on the use of a simple and effective approach to overcome this limitation using amphiphiles. An amphiphile (from the Greek amphis: both and philia: friendship) is a molecule containing both a water “loving” part (hydrophilic) and a water “hating” part (hydrophobic). Amphiphiles are used widely used in detergents for their ability to lift the oil or grease in water due their bifunctional (amphiphilic) character.

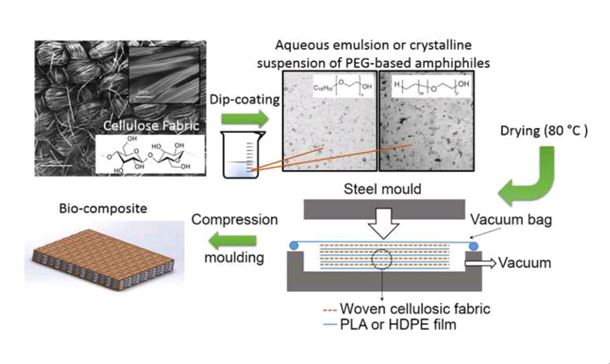

By mimicking this same concept, and by cleverly tuning both the amphiphilicity and the nature of the building blocks constituting the amphiphile, the authors were able to remarkably enhance the mechanical and durability performance of a of cellulose-based bio-composites, which were fabricated by an alternative, greener route in comparison to traditional chemical methods, with either polylactide (PLA) or high density polyethylene (HDPE) as a matrix, which are two polymers of industrial relevance.

Dr Magniez, lead author of the article, said: “We believe the outcomes of our study provides a technological template to significantly improve the performance of currently used bio-composite materials.”

Moving on to the next step in their research, Dr Magniez is now looking at other functional composite materials including carbon fibers reinforced composites.

Download the article relating to this news item here.