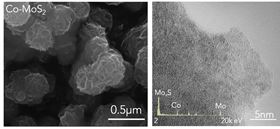

These microscope images at different magnifications show cobalt-doped molybdenum disulfide as grown on a carbon cloth. Image: Lou Group/Rice University.

These microscope images at different magnifications show cobalt-doped molybdenum disulfide as grown on a carbon cloth. Image: Lou Group/Rice University.Researchers at Rice University have developed an inorganic method for synthesizing ammonia that is both environmentally friendly and can produce the valuable chemical on demand under ambient conditions.

The lab of materials scientist Jun Lou has turned a two-dimensional (2D) crystal it understands well – molybdenum disulfide – into a catalyst by removing atoms of sulfur from the latticelike structure and replacing the exposed molybdenum with cobalt. The resulting material was able to mimic the natural organic process bacteria use to turn atmospheric dinitrogen into ammonia in organisms, including humans, that use ammonia for liver function.

The inorganic process will allow ammonia to be produced anywhere it's needed as a small-scale adjunct to industry, which produces millions of tons of the chemical each year through the inorganic Haber-Bosch process. The researchers report their work in a paper in the Journal of the American Chemical Society.

"The Haber-Bosch process produces a lot of carbon dioxide and consumes a lot of energy," said co-lead author and Rice graduate student Xiaoyin Tian. "But our process uses electricity to trigger the catalyst. We can get that from solar or wind."

The researchers already knew that molybdenum disulfide had an affinity to bond with dinitrogen, a naturally occurring molecule comprising two strongly bonded nitrogen atoms that forms about 78% of the Earth's atmosphere. Computational simulations by Mingjie Liu, a research associate at Brookhaven National Laboratory, showed that replacing some exposed molybdenum atoms with cobalt would enhance the compound's ability to reduce dinitrogen to ammonia.

Lab tests at Rice confirmed this was so. The researchers assembled samples of the nanoscale material by growing defective molybdenum disulfide crystals on carbon cloth and adding cobalt. (The crystals are technically 2D but appear as a plane of molybdenum atoms with layers of sulfur atoms above and below.) When a current was applied, 1kg of this 2D catalyst could yield more than 10 grams of ammonia per hour.

"The scale is not comparable to well-developed industrial processes, but it can be an alternative in specific cases," said co-lead author Jing Zhang, a postdoctoral researcher at Rice. "It will allow the production of ammonia where there is no industrial plant, and even in space applications." He added that while lab experiments used dedicated feeds of dinitrogen, the platform can just as easily pull it from the air.

According to Lou, other dopants may allow the material to catalyze other chemicals, a topic for future studies. "We thought there was an opportunity here to take something we're very familiar with and try to do what nature has been doing for billions of years," he said. "If we design a reactor the right way, the platform can carry out its function without interruption."

This story is adapted from material from Rice University, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier. Link to original source.